Machining Capabilities

-

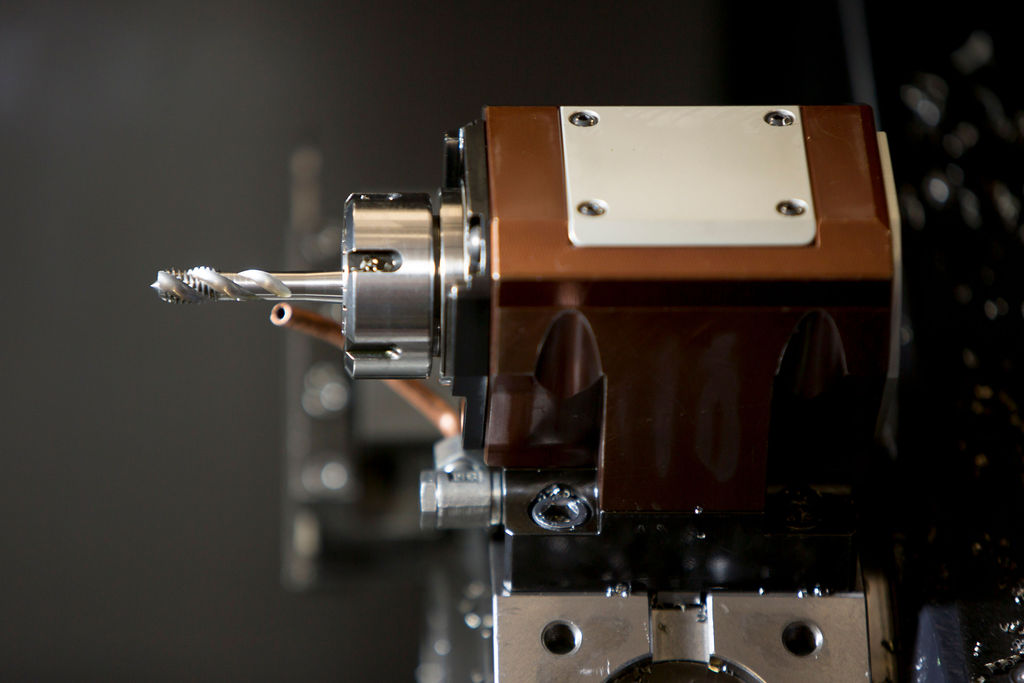

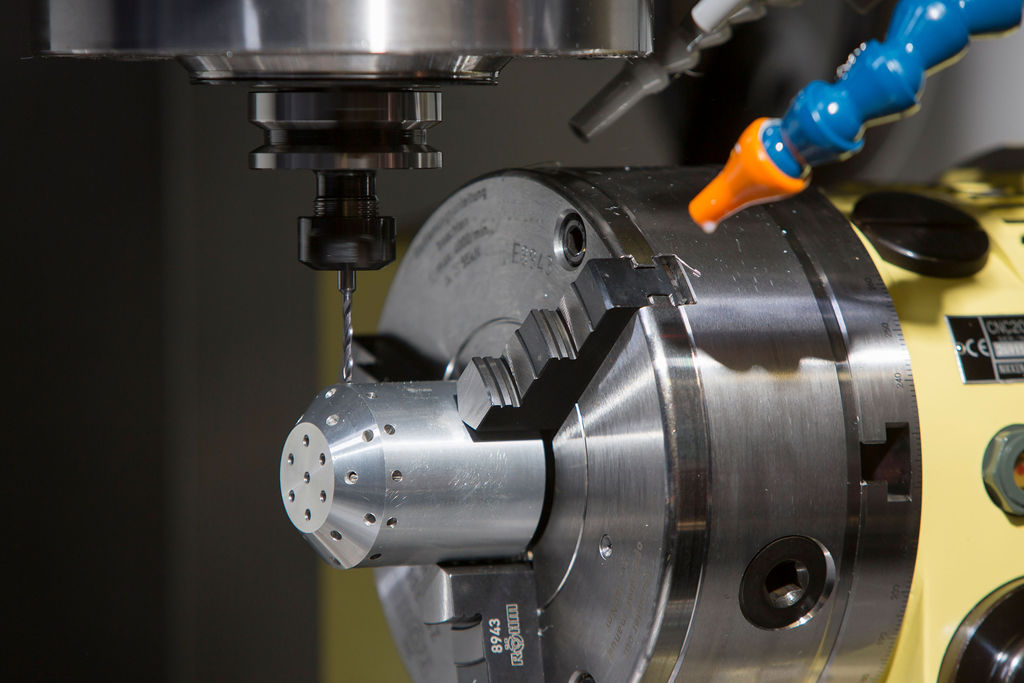

Doosan GT2100: milling/turning with a maximum turning diameter of 350mm, length 560mm, spindle bore 65mm

-

Doosan G2100: milling/turning with a 1.5 metre bar feed

-

Doosan DNM 5700 with 4th axis: bed size 1000mm x 570, height capacity 510mm

-

Colchester Mastiff: 1400 manual lathe

-

Bridgeport manual milling machine

-

Welding plants: Mig and Tig

-

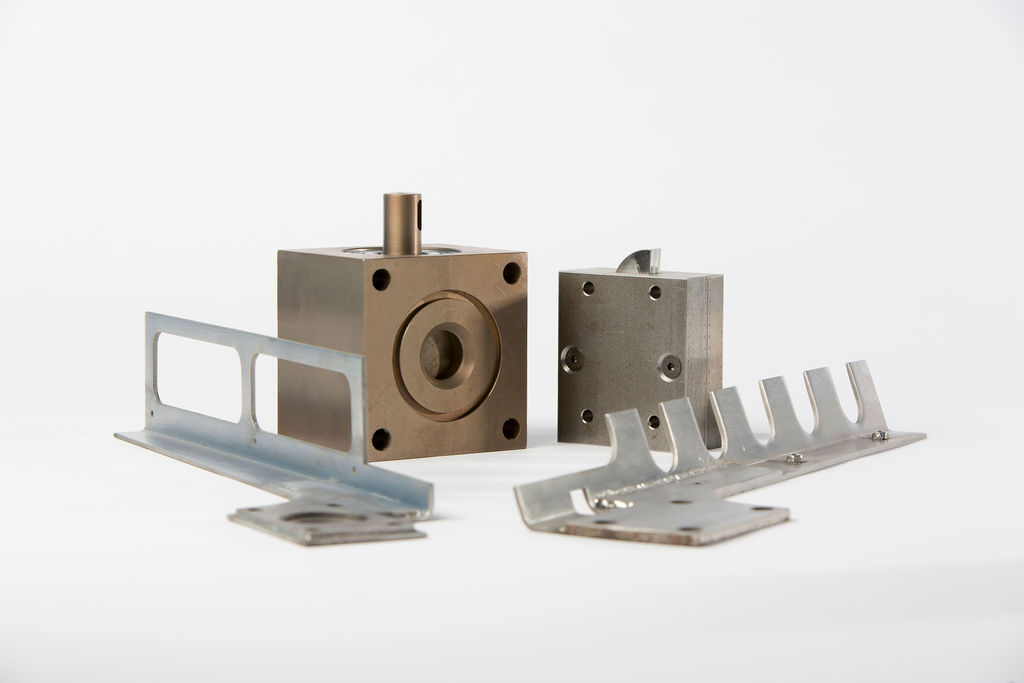

Additional services include fabrication, wire eroding, gear cutting and anodising

-

Material treatments include colour anodising, case hardening and hard chroming

Our manufacturing capability is extremely flexible: we can produce everything from bespoke one-off parts to high-volume, mass-produced components.

Reverse engineering

It doesn’t matter if you haven’t got a drawing. As long as you have a sample (new or old) we can reverse engineer to make new precision parts.

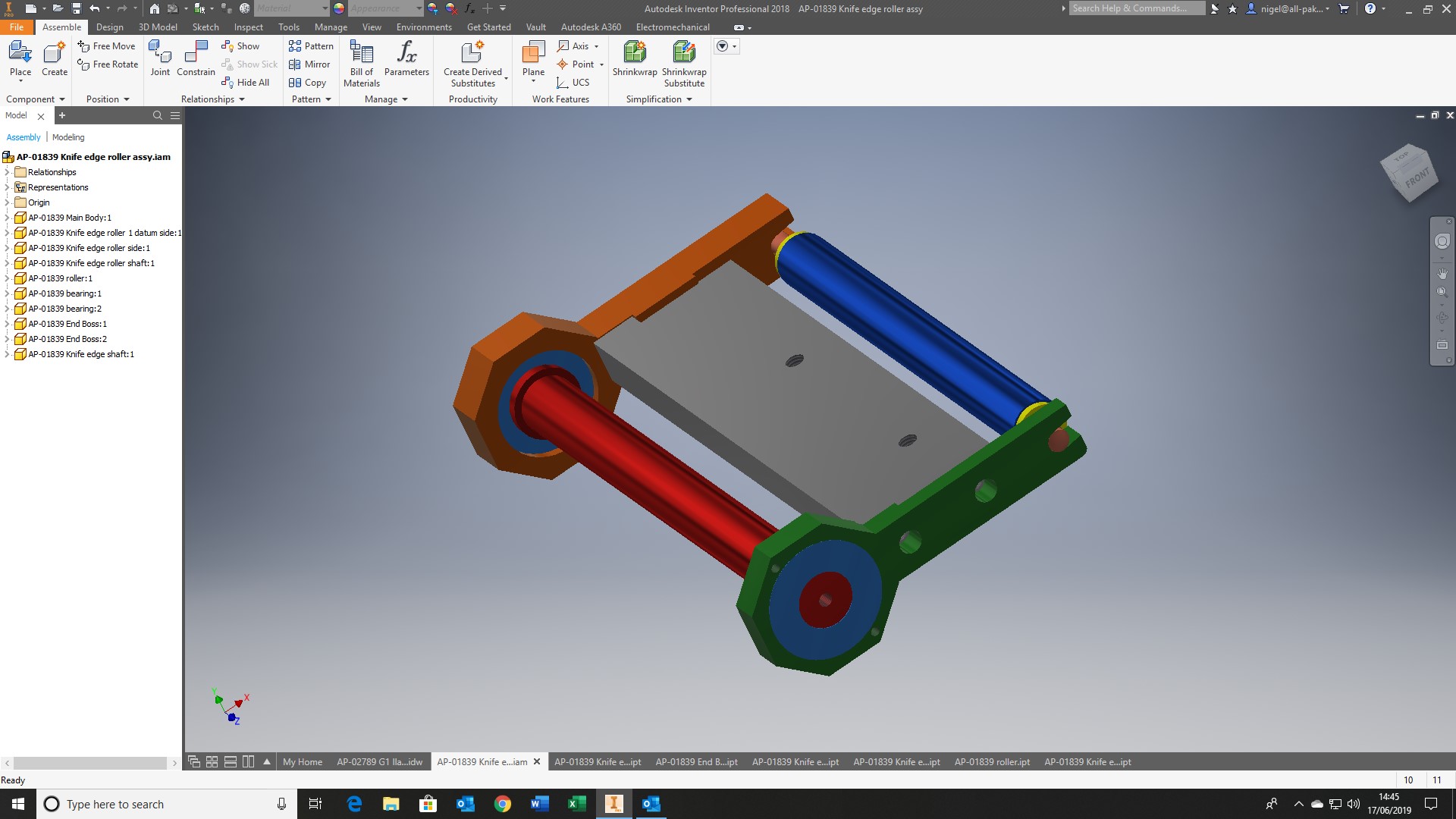

Software

Our team has the latest Autocad Inventor 3 dimensional drawing software. This allows us to design even the most complex components. Once these have been drawn we can build them, in the process highlighting any discrepancies or necessary modifications.

To produce programmes for complex components, we work offline using the very latest Feature-Cam package.